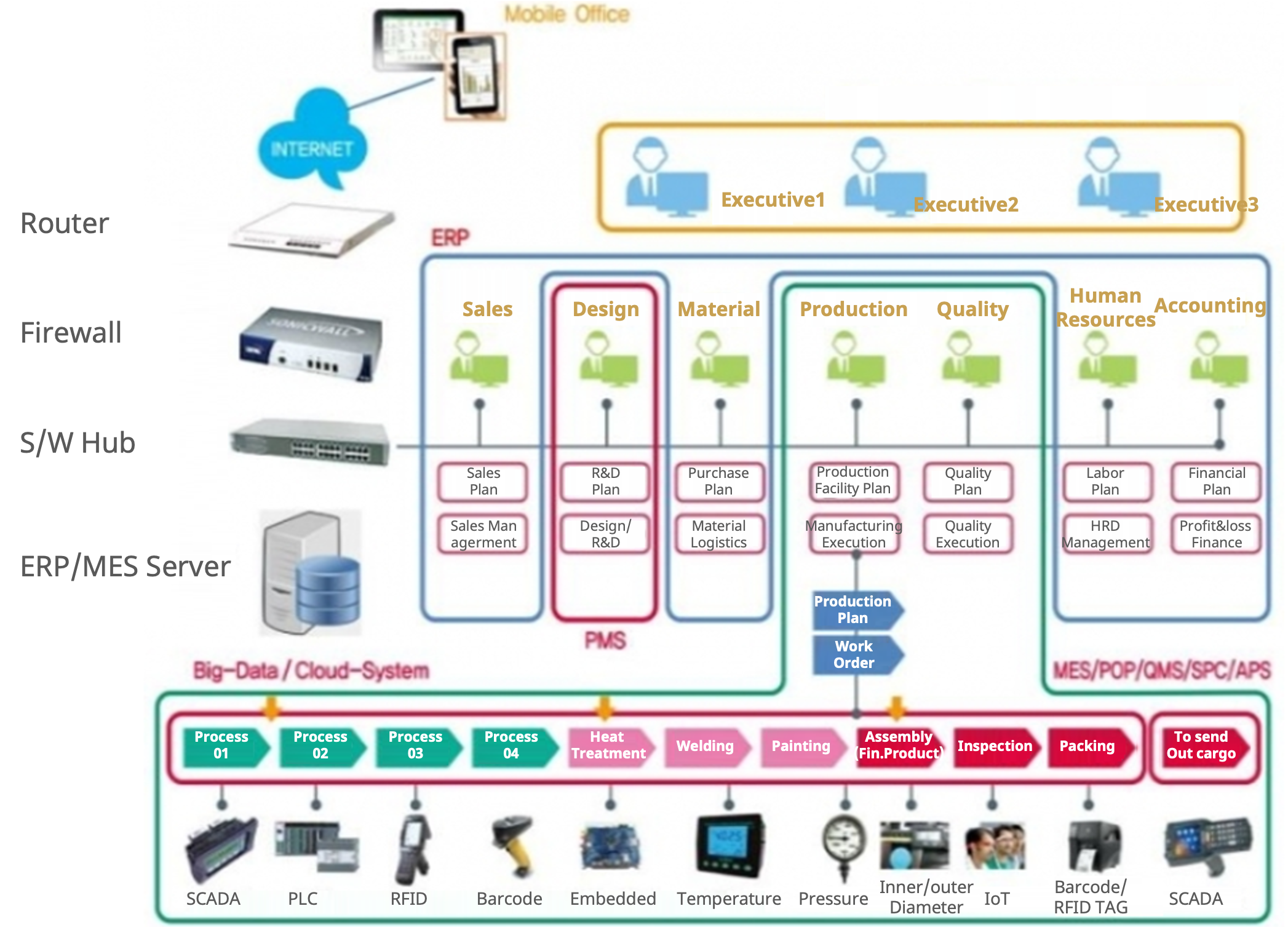

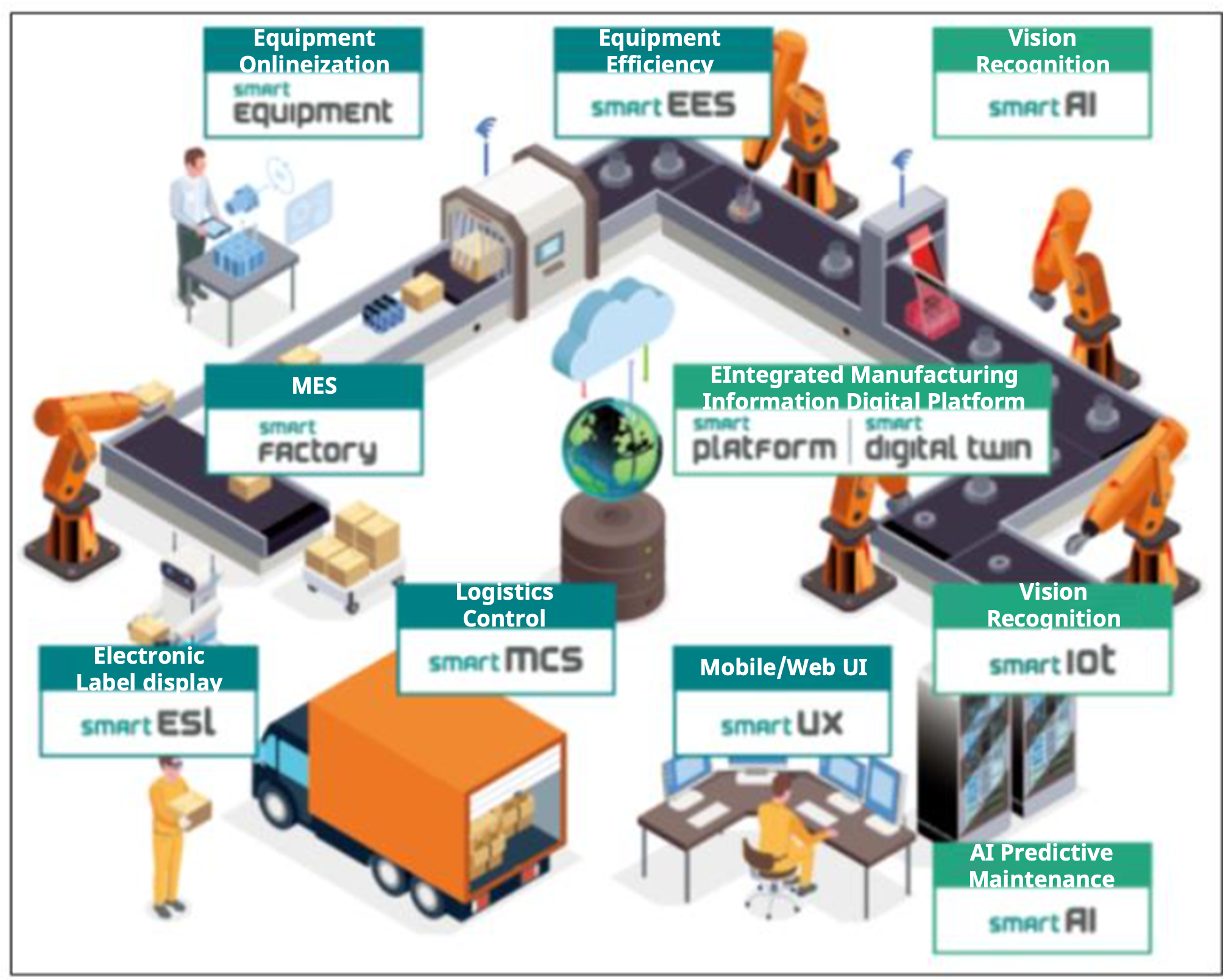

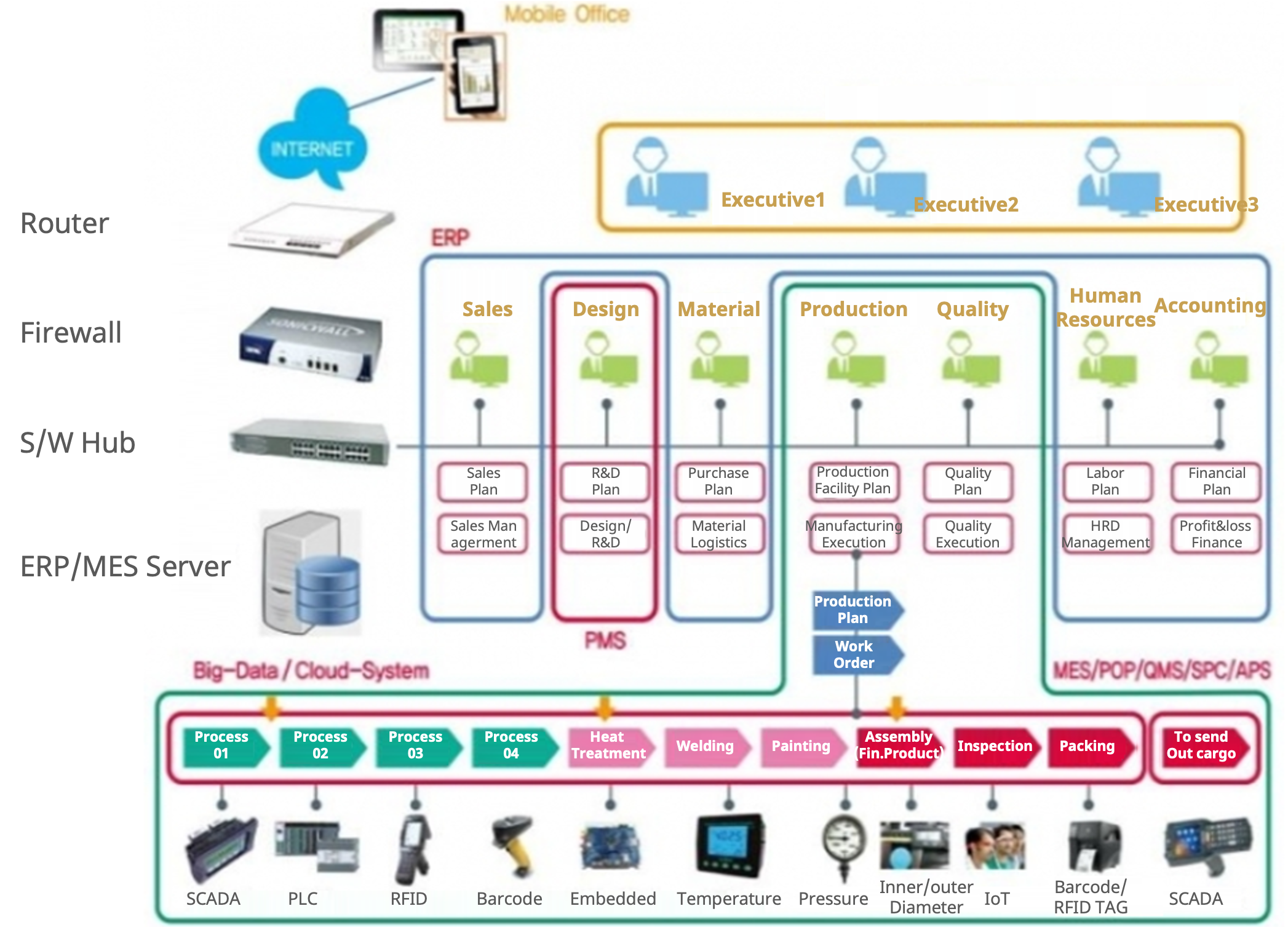

It is a solution that enables data integration and systematic IT

management through ERP (Enterprise Resource Planning) and MES

(Manufacturing Execution System), and is user-friendly and highly

secure.

Business competitiveness and productivity improvement

Operate sales, production, purchasing, logistics, personnel,

accounting, etc. of the company as one integrated system

Digitalization from production management, manufacturing

standard document creation to product shipment

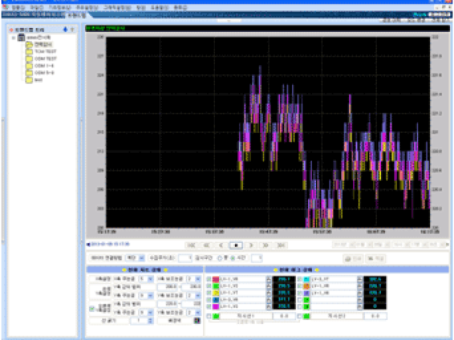

Monitor production data in real time, check inventory status,

track orders, manage payment processes, generate reports, and

enhance collaboration with teams

Operate your business smoothly anytime, anywhere through the

mobile app. Receive important business notifications in real

time