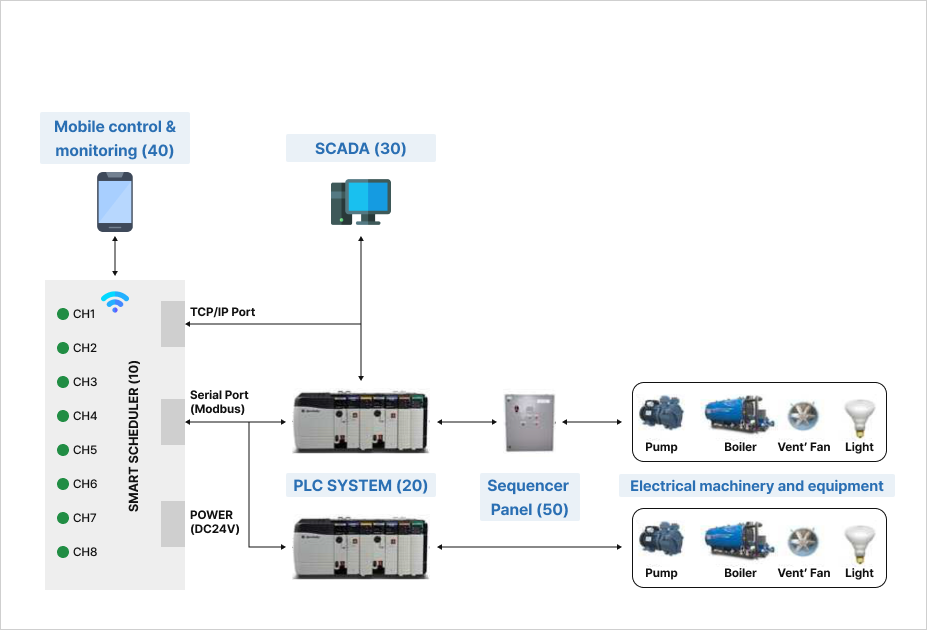

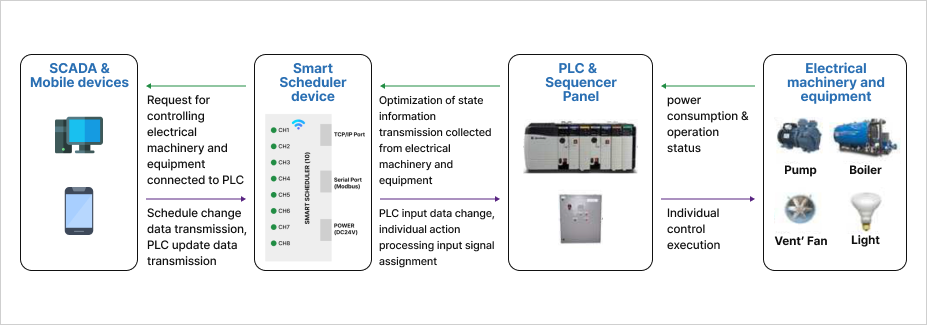

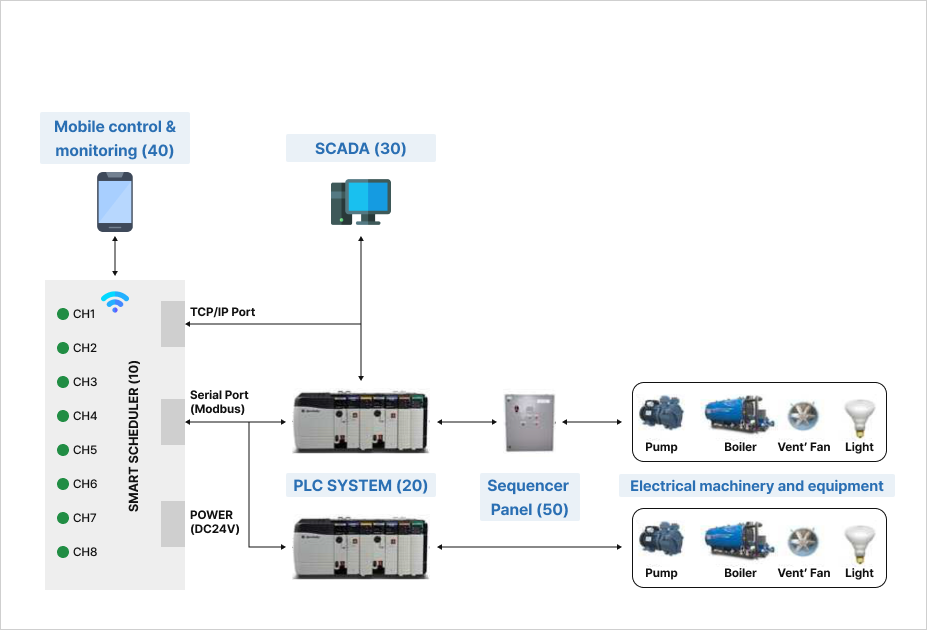

Smart Scheduler Device Data Flow

Collect electric machine data in conjunction with

PLC(Programmable Logic Controller). Collection and analysis of

operation information

Send/receive information to SCADA system(Intensive remote

monitoring and control system) through TCP/IP PORT

The SCADA system computerizes the standard usage time of

electrical machinery, individual selection, errors, and alarm

details through an information computer aggregation program

based on the received data.

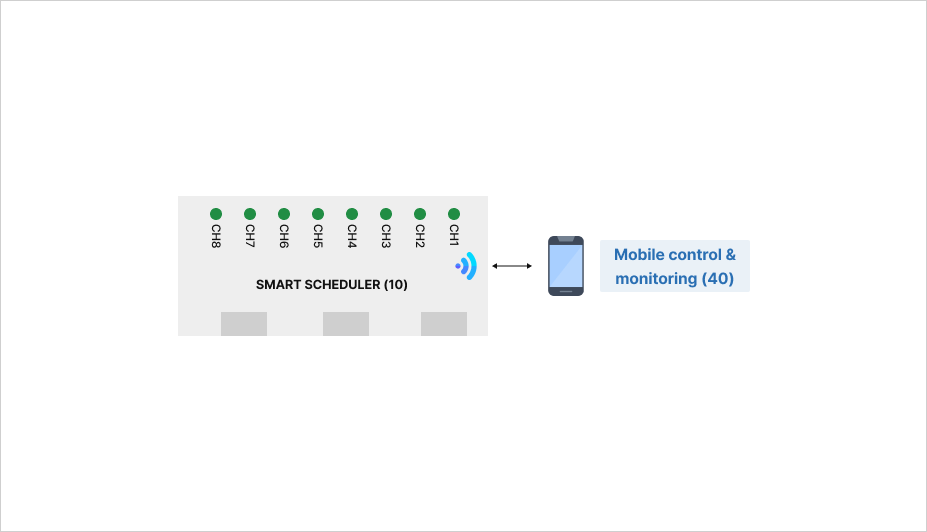

Transmission to mobile devices such as smartphones or smart

pads, monitoring of electromechanical devices and remote

schedule control