SI MANAGER

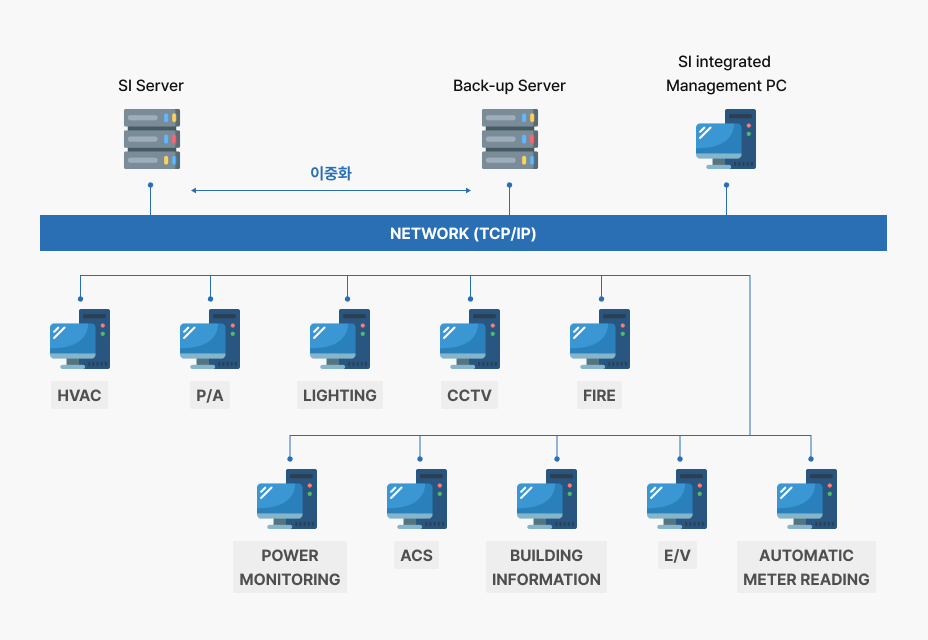

Two or more server duplication functions for stable server

operation

In case of malfunction of the main server, control functions are

transmitted in real time to the backup server to maintain

service

Implementation of uninterrupted management service 24 hours/365

days

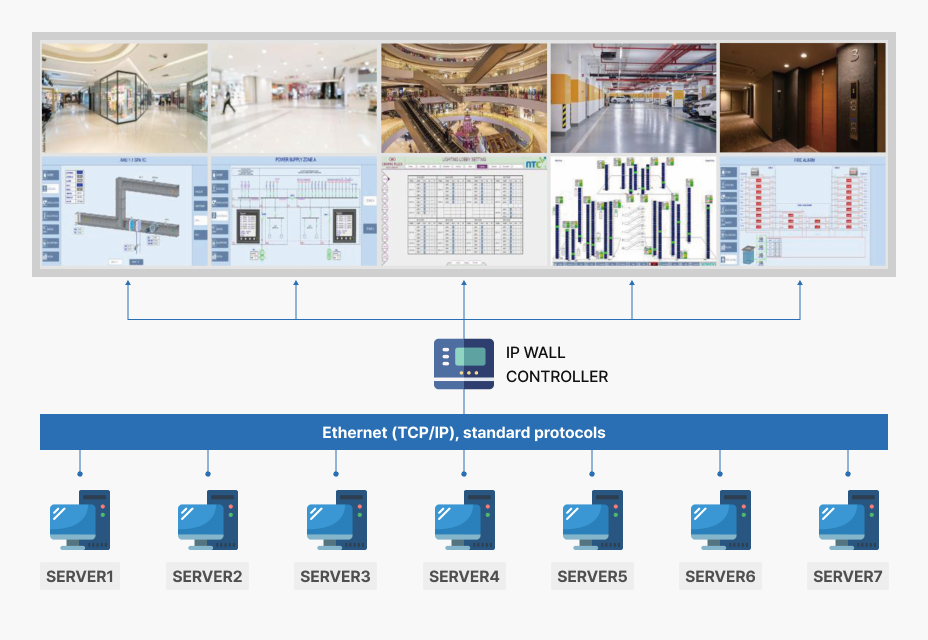

Provides monitoring and control functions for each process

individual server

Provides control issues and status monitoring information to

operators by PC and mobile

Provides communication methods to enable various facilities and

interfaces, and enables intuitive GUI implementation